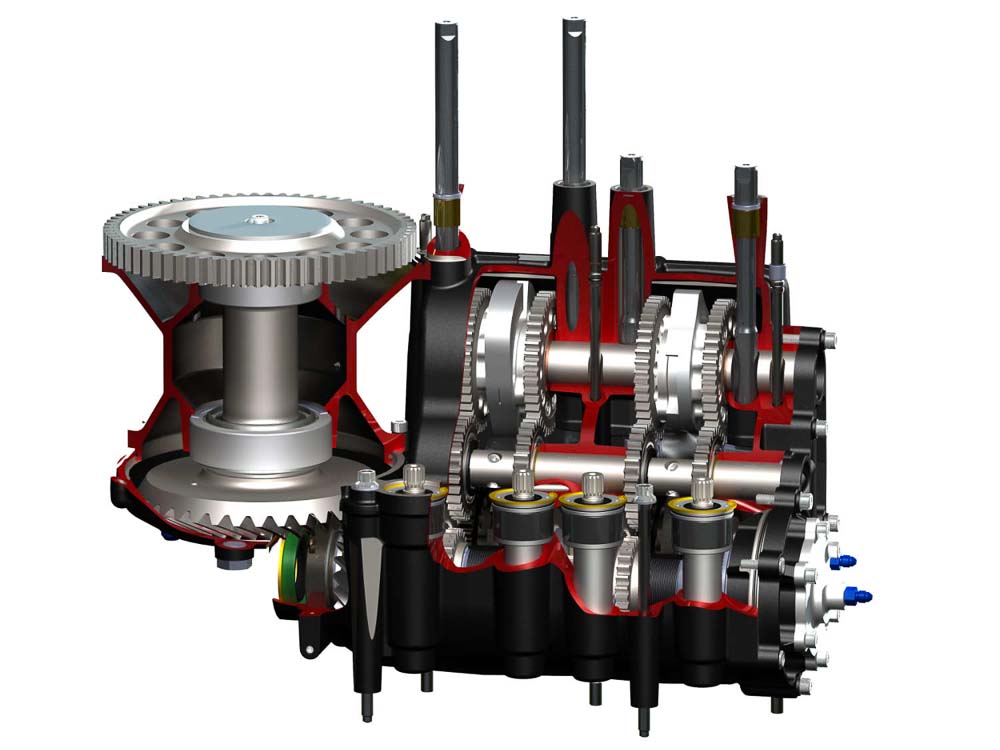

Industrial Variable Phasing Drive Gearbox

Concept, Design and Part Supply

The brief for this design within a design was generated by Acrokin, the client gave us a very concise specification for an air compressor/ expander machine. The power, speed, cost, pressure, life, performance and isothermal targets were specified. The architecture was to be a reciprocating piston type machine. We presented a machine design and introduced a series of enabling innovations. Patents protect innovations such as the mechanism to both drive the valve actuation cams and slew their angular position relative to the drive. The ability to slew was key to maintaining optimum timing as the tank pressure changed, and to change the amount of power produced in expander mode.

The design had to be robust to achieve the life target and low friction to reduce parasitic losses. By using a worm and wheel the position of the timing could be maintained without constant actuator torque and the high ratio reduced the actuator size. The slew mechanism utilized the three legs of a planetary gear assembly, one as drive torque in, one as drive out and one to slew, the 4 planetary drives where packaged into one gearcasing with the valve actuation cams to give control of the High pressure valve opening and closing as well as the Low pressure valve opening and closing.

Acrokin worked with their specialized manufacturing partners for shafts, gears, cams and the gearbox casings while the clients procurement team sourced the balance of the assembly parts.

Assembly tools and documentation were supplied to ensure correct assembly technique. Reliability and lubrication optimization testing were successfully undertaken at the clients facility in partnership with Acrokin Engineers.